Medical Equipment Suppliers in Gauteng

Gauteng’s operating theaters are modernizing at pace, yet hospitals still value the traditional relationship-driven way of doing business. That duality creates a real opening for medical equipment suppliers in Gauteng who can pair disciplined products with dependable service and a respectful presence in the OR. Ortonom Medical focuses on orthopedic prostheses and complete instrument sets, so our message to committees is simple and teachable: one coherent system, supported well, and ready for repeatable outcomes.

Volumes are rising across Johannesburg, Pretoria Tshwane, and Ekurhuleni as survivorship after trauma improves and ageing curves extend. Administrators are being measured on predictability, not just price, and they want fewer brands with clearer accountability. In that climate, medical equipment suppliers in Gauteng earn trust by aligning stock to real case cadence, keeping dossiers audit-ready, and showing up at key moments in the surgical pathway. Reliability is the most traditional promise in healthcare—and it still wins.

Clinical teams need more than a catalog. With rotating staff and visiting surgeons, instruments must be intuitive and trays must be laid out in a way that new scrub teams can learn quickly. Ortonom’s knee and hip families were designed as systems, not parts bins, so each step is logical and each verification point is obvious. For medical equipment suppliers in Gauteng, this teachability shortens onboarding, reduces anxiety in theater, and builds surgeon loyalty case after case.

Committees remember calm execution. When documents pass on the first submission, when lead times are honest and kept, and when the tenth case feels as smooth as the first, decision makers stop shopping around. Ortonom treats documentation and training as part of the product, not an afterthought, so a partner who positions us among medical equipment suppliers in Gauteng can submit once, launch once, and build momentum without drama.

What Ortonom Medical brings to Gauteng hospitals

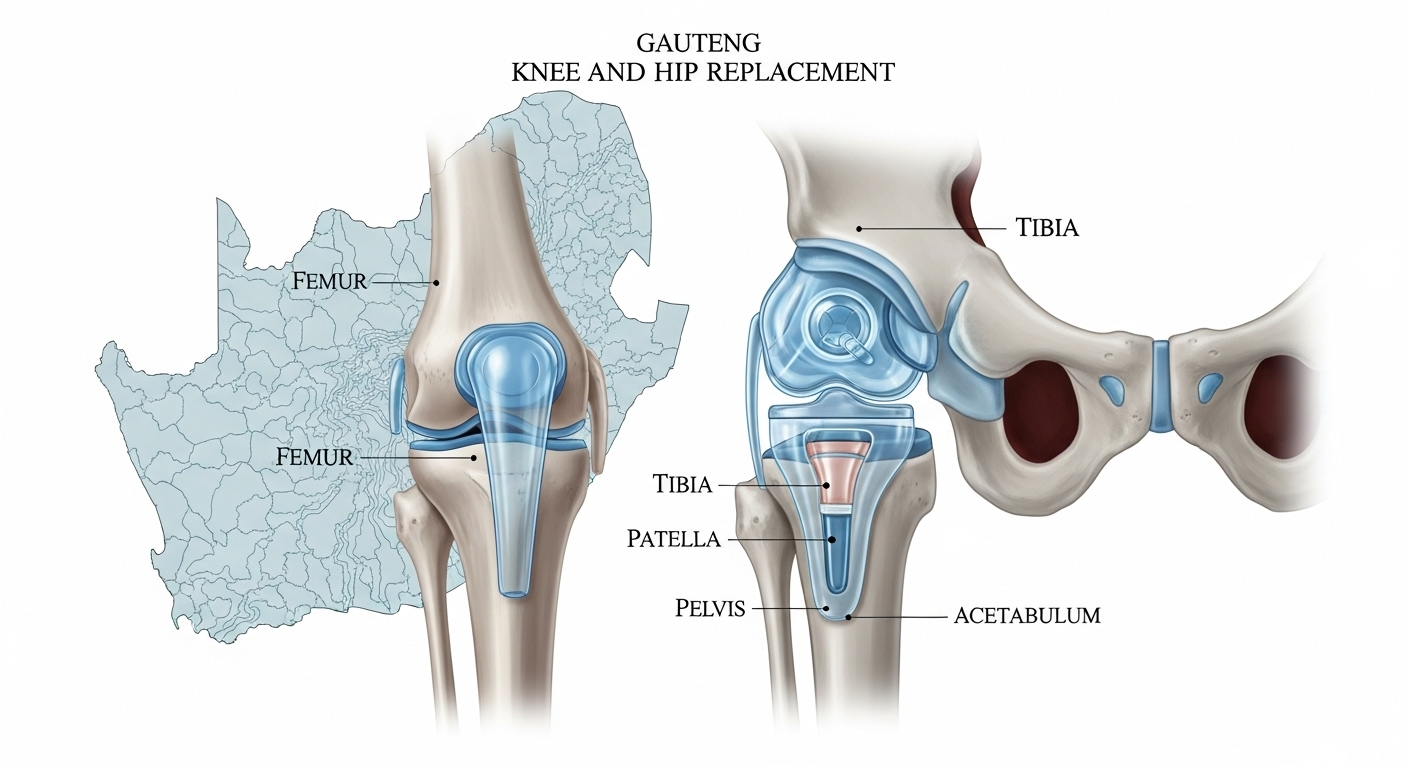

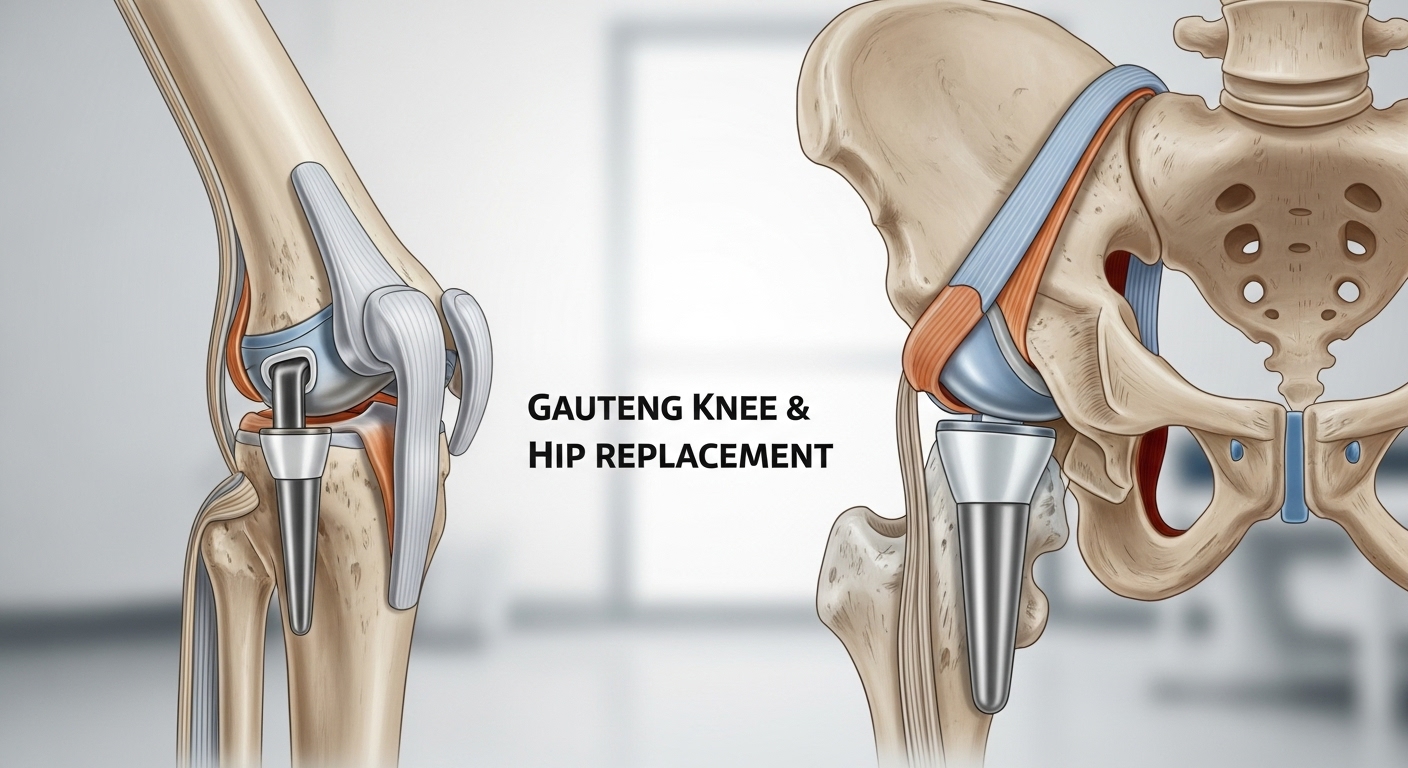

Ortonom Medical’s portfolio centers on knee and hip prostheses supported by complete, teachable instrument sets. In knee arthroplasty, the femoral component, tibial baseplate, polyethylene insert, and patella are validated to work together across sizes, and trial components make gap logic unambiguous. In hip reconstruction, stems, cups, and heads are engineered for stable fixation and surface integrity, with instrumentation that supports alignment and reproducibility. This coherence helps medical equipment suppliers in Gauteng present a pathway, not a pile of SKUs.

Documentation is treated like a clinical tool. Technical files, labels, and IFUs arrive in committee-ready formats, paired with tray checklists that CSSD can adopt as standard work. That discipline reduces reformatting cycles and customs friction, moving first cases forward faster. For partners competing among medical equipment suppliers in Gauteng, fewer document surprises translate into earlier revenue, fewer escalations, and better word-of-mouth inside hospital networks.

Enablement is continuous. We provide bilingual EN FR training decks, short technique videos, and pocket checklists that staff can use between cases. Launch workshops focus on the moves that matter—distal and posterior resections, tibial slope and rotation, insert selection, and patellar tracking—then we shadow early cases so teams feel supported. This loop converts clinical feedback into stock signals, helping medical equipment suppliers in Gauteng tune their starter matrices to real usage.

Service closes the loop. Fast instrument turnaround, accessible spares, and clear incident pathways determine whether a strong first week becomes a stable first year. We plan preventive maintenance with CSSD, offer consignment for fast movers, and keep dashboards simple and shared. Over time, that steadiness becomes the signature of successful medical equipment suppliers in Gauteng.

Product snapshot for knee and hip systems

The table below summarizes Ortonom Medical’s core systems you can position in Gauteng committees. It is an aide-mémoire for workshops and tender pages.

| Family | System | Core features | Typical use cases | Training focus |

|---|---|---|---|---|

| OrtoKnee | Fixed Knee System | CR pathway option, intuitive size ladder, robust locking interface | Primary knee with intact or reconstructable PCL | Gap logic, insert selection, patellar tracking |

| OrtoKnee | Mobile Knee System | Mobile-bearing inserts, mid-flexion stability emphasis | Higher-demand primaries | Rotation checks, tibial alignment consistency |

| OrtoKnee | Revision Knee System | Augments, stems, constraint options | Complex or revision TKA | Constraint selection, bone defect management |

| OrtoHip | Total Hip System | Press-fit and cemented options, alignment cues in instruments | Primary THA | Offset management, leg-length checks |

| OrtoHip | Bipolar Hip System | Bipolar head options, streamlined instrumentation | Fracture management | Capsule handling, stability checks |

| OrtoHip | K2 Revision Hip System | Modular stems, multiple fixation strategies | Complex or revision THA | Taper integrity, extraction workflows |

This snapshot does not replace training; it guides it. A one-page spec sheet built from this table helps medical equipment suppliers in Gauteng equip chiefs of service to brief procurement, CSSD, and finance with minimal friction.

Why this architecture solves everyday problems

First, it shortens learning curves for rotating teams. Labeled handles, color cues, and tray order match the operative sequence, so staff navigate the case without guesswork. Second, it makes balancing decisions visible through trial components that step in predictable thickness increments. Third, it protects instrument life by reducing unnecessary exchanges and by using surface finishes that resist micro-scratches during trials. Fourth, it makes committee conversations easier because the system is coherent; questions about size coverage, insert logic, and patellar strategy have crisp answers.

For medical equipment suppliers in Gauteng, those four benefits become your case for standardization. Standardization reduces hidden costs—emergency freight, tray rebuilds, overtime—and it creates predictable lists that administrators can schedule with confidence. That is how a clinical pathway turns into a commercial moat.

How to win hospital committees and tenders in Gauteng

Winning starts with a hospital-ready narrative. Lead with the clinical pathway, show the component logic at a glance, and present realistic lead times that you intend to keep. The most credible medical equipment suppliers in Gauteng do not promise everything; they promise what they can deliver and then deliver it. Committees reward this mix of clarity and restraint.

Turn training into a habit. Hospitals do not just buy implants; they buy confidence in outcomes. Schedule workshops for surgeons and scrub teams, then supervise first cases so teams feel supported. Document early results and capture preferences—insert thickness distributions, patella resurfacing patterns, alignment choices. Feed those insights back into the stock matrix and tender language. This is where medical equipment suppliers in Gauteng shift from vendor to partner.

Share data that matters. Keep a simple dashboard for each site—instrument turnaround, safety stock status, open cases, and replenishment due dates—and invite hospital counterparts to the same view. When delays happen, communicate early with a remedy plan and a date you can keep. Under promise and over deliver is an old rule because it works, especially for medical equipment suppliers in Gauteng competing in public frameworks.

Respect tradition while using modern tools. Face-to-face mentoring, presence in the theater, and steady follow-through still win the day. QR-coded IFUs, digital checklists, and 90-second micro-videos simply let you scale those timeless behaviors. The blend of trusted presence and transparent process is what committees reward and what turns first cases into renewals.

Gauteng market snapshot and rollout plan

Use the table to sequence launches, tailor training calendars, and shape a starter stock matrix that matches early case cadence across the province.

| City or District | Typical channels | First focus procedures | What wins quickly | Notes for distributor |

|---|---|---|---|---|

| Johannesburg | Private plus public tenders | Primary knee and hip | OR presence, fast instrument turnaround | Anchor lighthouse references |

| Pretoria Tshwane | Public teaching and private | Standardized knee pathways | Bilingual briefs, conservative lead times | Strong CSSD coordination |

| Ekurhuleni | Private hospitals | Knee primary familiar flows | Clear IFUs, service SLAs | Emphasize sterilization guidance |

| West Rand | Public | Trauma to arthroplasty conversions | Reliable replenishment | Capture data to tune inserts |

| Sedibeng | Public plus NGO | Mixed orthopedic load | Documentation that passes first time | Build references for tenders |

Begin with two lighthouse sites—one high-volume metro in Johannesburg and one fast-decision site in Pretoria or Ekurhuleni. Ten to twelve clean cases per site, summarized in bilingual outcome briefs, will establish credibility. As momentum grows, expand to West Rand and Sedibeng to prove repeatability across different hospital environments. This is a low-risk way for medical equipment suppliers in Gauteng to scale without diluting focus.

Plan calendars with the real OR list in mind. Weekday workshops with evening refreshers suit Johannesburg, while half-day sessions around clinic days may work better in Pretoria. Publish micro-videos linked to key steps—distal femoral cut, tibial slope and rotation checks, patella tracking in trial—so rotating staff can refresh in minutes. These habits quietly lower variability while raising confidence.

Keep the stock honest. Measure insert thickness distribution, instrument wear, and shelf age of slow movers. Adjust the matrix before drift appears. When committees ask how you prevent stockouts and dead stock, show your method and the last improvement you made. Over time, disciplined truth-telling is how medical equipment suppliers in Gauteng become the safe choice.

Finally, elevate surgeon champions. Invite respected operators to co-host workshops and to brief administrators during committees. Peer reference moves rooms faster than brochures. If the product is sound and the service is steady, champions will speak up—and that is your most traditional and most effective proof.

Clarity on roles prevents disappointment and protects credibility. Use this RACI-style table in proposals and launch packs.

| Item | Ortonom Medical provides | Partner commits | Typical timeline |

|---|---|---|---|

| Regulatory dossier | Technical files, labels, IFUs in committee format | Local submission, tracking, meeting attendance | 5–15 business days per pack |

| Launch training | Surgeon and nurse workshops EN FR videos | Venue, attendee coordination, refresher plan | Within 30 days of appointment |

| Instrument readiness | Tray checklists, sterilization guidance, maintenance | CSSD capacity, maintenance schedule | Pre-launch plus quarterly |

| Inventory policy | Stock matrix, reorder points, consignment options | Safety stock, monthly reporting | Agreed at contract, reviewed monthly |

| Field support | Case shadowing remote or in person troubleshooting | Case scheduling, structured feedback loop | First 3–6 months |

| Country copy | Bilingual brochures, listing text, FAQs | Localization, response SLAs | Live at launch, quarterly updates |

Publishing and keeping these commitments is the most persuasive marketing a partner can do. In competitive rooms, the medical equipment suppliers in Gauteng who attach realistic SLAs—and then meet them—win quietly and win often.

Operations, compliance, and logistics you can keep

Procurement leaders in Gauteng want two outcomes above all: files that pass on the first try and stock that arrives when promised. We set conservative lead times, define what can be consigned locally, and convert early case data into reorder logic. In tender rooms, those truths are worth more than slogans. The medical equipment suppliers in Gauteng who keep calm schedules become the default option when stakes are high.

Compliance is continuous, not a one-off upload. Expect audits, label tweaks, and IFU updates as hospital protocols evolve. Ortonom maintains version-controlled masters so updates flow cleanly from factory to distributor to hospital. Your regulatory manager will have a named counterpart at Ortonom—old-fashioned accountability that saves modern time. That rhythm protects deals and keeps teams aligned.

Logistics should be predictable in the best sense. Stage fast movers—mid sizes and common insert thicknesses—in province, rotate long-tail sizes from regional hubs, and tie reorder points to real case cadence rather than optimistic forecasts. Publish those rules in proposals and committee briefs. Over a few quarters, a reliable pipeline becomes your brand as one of the dependable medical equipment suppliers in Gauteng.

Service makes loyalty visible. Quick instrument turnaround, defined incident paths, and scheduled check-ins after early cases prove that support is a strategy, not a cost. Administrators remember who solved problems quickly. Surgeons remember who stood next to them when it mattered. In renewals, that memory often beats a small price edge—and it is how strong medical equipment suppliers in Gauteng sustain position.

Ninety-day launch plan and partner invitation

Prepare weeks 1–3. Finalize bilingual decks, IFUs, and a one-page spec snapshot. Confirm the regulatory bundle and pre-clear customs documents where possible. Build a starter stock matrix aligned to expected case cadence at your two lighthouse hospitals. Book workshop dates and block theater slots for supervised first cases. Position your story clearly around being among the most credible medical equipment suppliers in Gauteng—teachable, documented, and deliverable.

Train weeks 4–6. Run workshops for surgeons and scrub teams and supervise first cases. Emphasize verification steps that protect outcomes: distal femoral resection checks, tibial slope and rotation, and patella tracking in trial. Capture preferences and update checklists, FAQs, and reorder logic.

Execute weeks 7–10. Complete ten to twelve cases per site. Debrief with teams, tune inventory—especially insert thickness distribution—and align instrument maintenance with CSSD. Publish honest lead times and keep them. If a logistics lane slows, inform committees early and propose a workaround.

Scale weeks 11–13. Add one more Gauteng hospital and prepare the next-region pack. Approach public frameworks once private references are documented. Provide outcome summaries, stable SLAs, and a clear after-sales plan. This blend of tradition and transparency is what sustains success for medical equipment suppliers in Gauteng.

If you bring hospital access, field discipline, and a service-first culture, Ortonom Medical will bring focused implants, teachable instruments, and dossiers that pass. Let us schedule the first workshops, run the first cases, and build references that open tenders and renewals—one successful procedure at a time.

Ortonomy refers to the study and application of principles related to the proper function and structure of systems, especially in biological or technological contexts. In medical terms, it often refers to the alignment and balance of body structures.

Ortonomy refers to the study and application of principles related to the proper function and structure of systems, especially in biological or technological contexts. In medical terms, it often refers to the alignment and balance of body structures.